Annual Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2015

Annual Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2015(PDF 5697 kb)

Table of Contents

- 1 Background

- 2 Report overview

- 3 Regulatory program for the use of nuclear substances

- 3.1 CNSC regulatory effort

- 3.2 Licensing

- 3.3 Certification of prescribed equipment

- 3.4 Certification of exposure device operators

- 3.5 Certification of Class II radiation safety officers

- 3.6 RSO appointment for nuclear substances and radiation device licences

- 3.7 Licensing and certification decisions

- 3.8 Compliance verification and enforcement

- 3.9 Reporting

- 3.10 Stakeholder engagement

- 4 Regulatory developments

- 4.1 Packaging and Transport of Nuclear Substances Regulations, 2015

- 4.2 REGDOC-1.6.1, Licence Application Guide: Nuclear Substances and Radiation Devices

- 4.3 REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources

- 4.4 Financial guarantee licence condition

- 4.5 CSA Standard PCP-09, Certified Exposure Device Operator Personnel Certification Guide

- 4.6 Guidance on the handling of the deceased implanted with nuclear substances

- 4.7 Regulatory focus in 2016

- 5 Safety performance – all sectors combined

- 6 Industrial sector

- 7 Industrial sector

- 8 Academic and research

- 9 Commercial sector

- 10 Conclusion

- Appendix A: Radiation exposure

- Appendix B: Safety and control area naming conventions

- Appendix C: Enforcement actions issued in 2015

- Appendix D: List of reported events in 2015

- Appendix E: Compliance rating levels

- Appendix F: Grading inspections

- Appendix G: Abbreviations and glossary

1 Background

The Canadian Nuclear Safety Commission (CNSC) regulates the use of nuclear energy and materials to protect health, safety, security and the environment; to implement Canada’s international commitments on the peaceful use of nuclear energy; and to disseminate objective scientific, technical and regulatory information to the public. Persons licensed by the CNSC are responsible for operating their facilities and managing their activities safely and are required to implement programs that make adequate provisions for protecting health, safety, security and the environment. The CNSC is responsible for setting the requirements and verifying compliance against those requirements.

Each year, CNSC staff assess the overall safety performance on the use of nuclear substances in Canada. Staff consider industry performance as a whole, as well as the performance of each sector (i.e., medical, industrial, academic and research, and commercial) separately. This assessment is summarized in this document.

For a comprehensive overview of the CNSC and its activities, consult the CNSC’s annual report, Regulating Nuclear Safety in Canada.

Regulatory oversight

The CNSC regulates the nuclear industry in Canada through a comprehensive program of licensing, certification, compliance verification and enforcement. For each nuclear industry sector described in this report, CNSC staff evaluate safety performance through inspections, assessments, reviews and evaluations of licensee programs and processes.

These regulatory programs cover various types of activities across all provinces and territories, as shown in Figure 1. Licensees include most hospitals in Canada, most Canadian universities and research institutions, and a wide variety of industrial manufacturing and production facilities including those that store, produce or service nuclear substances and devices.

The safe use of nuclear substances in Canada is demonstrated through licensees’ compliance with the Nuclear Safety and Control Act (NSCA) as well as its associated regulations, and specific conditions set out in CNSC licences. The NSCA, its regulations and the licences require that licensees implement and maintain appropriate programs to ensure the safety and security of nuclear-related activities, minimize doses to workers and the public, protect the environment, and minimize consequences of events.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Safety and control area framework

To ensure comprehensive regulatory oversight and reporting of licensed activities, CNSC staff have developed a set of safety and control areas (SCAs). SCAs have been in use for a number of years, and represent a well-established set of technical areas that have proven effective in evaluating licensee safety performance of regulated facilities and activities under the CNSC’s purview. The CNSC has defined 14 SCAs:

- management system

- human performance management

- operating performance

- safety analysis

- physical design

- fitness for service

- radiation protection

- conventional health and safety

- environmental protection

- emergency management and fire protection

- waste management

- security

- safeguards and non-proliferation

- packaging and transport

2 Report overview

This regulatory oversight report focuses on the results of compliance verification and enforcement activities in 2015 for licensees that use nuclear substances in four sectors:

- medical

- industrial

- academic and research

- commercial

Each sector performance is outlined in an individual section in this report.

The report does not cover uranium mines and mills, waste facilities, dosimetry services or Class I nuclear facilities such as nuclear power plants and nuclear research reactors. Also excluded as of 2015 are Class IB accelerator facilities, which will be covered in the Regulatory Oversight Report for Nuclear Processing, Small Research Reactors and Class IB Accelerator Facilities.

There are three parts to this report:

- regulatory process and developments

- overall industry safety performance assessment

- sector-specific safety performance assessments

2.1 Safety performance measures

CNSC staff review licensee documents and conduct field inspections to verify that licensees have implemented effective safety programs and practices. Results of these inspections provide information on key aspects of safety performance, within each SCA relevant to the licensed activity.

For the purpose of this report, the following four SCAs are the most relevant indicators of safety performance for licensees in the sectors covered in this report: management system, operating performance, radiation protection, and security. Compliance ratings – also referred to as inspection ratings – reflect overall licensee performance at a program level for each of these SCAs. The nature, type and safety significance of events reported by licensees, and the type of enforcement actions taken by the CNSC in 2015 are provided as supplementary indicators of safety performance. Data from 2011 to 2014 are included in figures for each of these safety indicators to identify five-year trends. Each performance measure is described below.

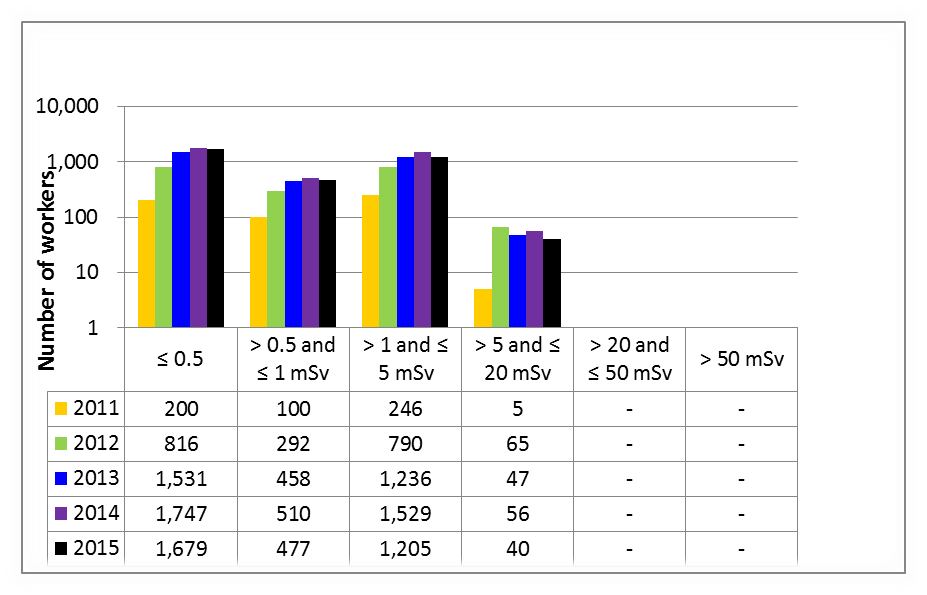

2.1.1 Doses to workers

All licensees are required to implement a radiation protection program that ensures that the radiation doses to workers are well below regulatory limits and kept as low as reasonably achievable (ALARA), with social and economic factors taken into account. Thus, ascertainment of the magnitude of doses received by workers is an integral part of a licensee’s radiation protection program.

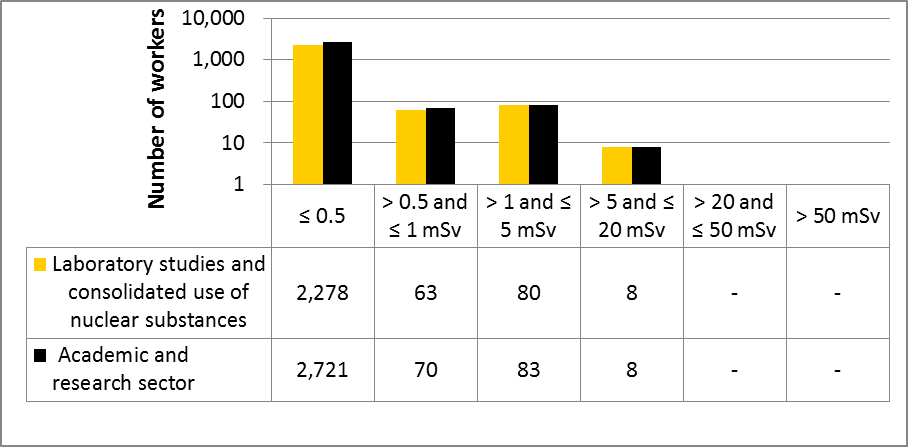

This report references two groups of workers that perform the types of work referenced in a CNSC licence: those designated as nuclear energy workers (NEWs) and those that are not designated as NEWs. The term NEW means a person who is required, in the course of his or her business or occupation in connection with a nuclear substance or nuclear facility, to perform duties in circumstances that may result in receiving a dose of radiation greater than 1 millisievert (mSv) per year. A worker not designated as a NEW means a person who is unlikely to receive a dose greater than 1 mSv per year while performing duties in connection with a nuclear substance or nuclear facility. This report provides dose information for all workers, while primarily focusing on those designated as NEWs.

The CNSC’s regulatory effective dose limits for NEWs are set at 50 mSv in any one-year dosimetry period and a total of 100 mSv over a five-year dosimetry period. The one-year dosimetry period covers January 1 to December 31 of every year. The five-year dosimetry period covered in this report started on January 1, 2011 and ended on December 31, 2015. During this period, none of the NEWs exceeded the five-year regulatory dose limit of 100 mSv. For all persons not designated as a nuclear energy worker, and for all members of the general public, the effective dose limit is 1 mSv per calendar year.

For activities where there is a need for direct handling of nuclear substances, doses to the hands are also monitored. These are known as extremity doses, and they are subject to a regulatory dose limit of 500 mSv in any one-year dosimetry period for NEWs and 50 mSv per calendar year for workers not designated as NEWs. The concept of a five-year dosimetry period is applied to neither extremity doses nor to the effective doses incurred by persons who are not NEWs.

Appendix A provides more information on occupational exposure, ascertaining worker doses and measures to be taken by licensees when a dose limit is exceeded.

2.1.2 Management system

For 2015, the regulatory oversight report now includes results of inspections ratings for the management system SCA. The sector-by-sector comparison is included in the overall section of the report and a summary of the inspection ratings is included for each sector.

The management system SCA covers the framework that establishes the processes and programs required to ensure that an organization achieves its safety objectives, continuously monitors its performance against those objectives, and fosters a healthy safety culture.

2.1.3 Operating performance

Operating performance refers to the licensee’s ability to perform licensed activities in accordance with pertinent operational and safety requirements defined in the NSCA, its associated regulations and licence conditions. Licensees are expected to demonstrate that they comply with operational and safety requirements by providing workers with appropriate procedures for the safe use of nuclear substances and prescribed equipment, by ensuring that workers follow procedures, and by maintaining records that demonstrate compliance. Operating performance is also referred to as “operational procedures” in the inspection reports provided to licensees of nuclear substances and radiation devices. Appendix B shows the mapping between the CNSC regulatory naming convention in the inspection reports and those presented in this report for SCAs.

2.1.4 Radiation protection

Radiation protection programs are required for every licensee to ensure that contamination levels and radiation doses received by workers are monitored, controlled and maintained below regulatory dose limits, and kept ALARA, social and economic factors being taken into account. Licensees can meet these objectives by monitoring worker doses; posting radiation warning signs; planning appropriately for radiological emergencies; managing oversight of operational activities; instituting effective workplace practices that emphasize the use of time, distance and shielding to minimize exposure to radiation; and using appropriate protective equipment.

2.1.5 Security

The security SCA covers the physical security measures, practices and programs that licensees are required to have in place to prevent the loss, illegal use, illegal possession or illegal removal of nuclear substances during their entire lifecycle, including while they are in storage or during transport. The extent of the security measures required depends upon the types of nuclear substances used and activities performed by each licensee.

The safety and security of sealed sources is increased through effective control and tracking. Routine CNSC compliance inspections include requirements to verify sealed source tracking information.

To ensure proper regulatory oversight of the new requirements related to the phased implementation of REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources, CNSC staff conduct enhanced security inspections for those in possession of category 1 and 2 sealed sources. Non-compliance details for these inspections are not included in this report due to their sensitive nature.

2.1.6 Enforcement actions

The CNSC may take a variety of compliance enforcement actions to ensure that licensees correct non-compliances in an effective and timely manner. The type of enforcement action taken is commensurate with the risk the non-compliance presents to the environment, the health and safety of workers and the public, and to national security. This report provides detailed information on the following types of enforcement actions taken by the CNSC: orders, administrative monetary penalties (AMPs), decertification of certified exposure device operators and decertification of radiation safety officers at Class II nuclear facilities. Appendix C provides a list of all orders and AMPs issued by the CNSC in 2015.

2.1.7 Reported events

Under the NSCA and its associated regulations, licensees are required to immediately report to the CNSC events related to their licensed activities that are of regulatory interest. Within 21 days of the initial report, licensees are required to submit a final report to the CNSC on the event. The final report must include an analysis of the cause and circumstances of the event, as well as any measures taken, or proposed to be taken, by the licensee to prevent recurrence. Together, the initial and final reports allow the CNSC to verify whether the licensee has taken appropriate measures to mitigate the event, and implemented adequate corrective actions to prevent recurrence.

The CNSC uses the International Nuclear and Radiological Event Scale tool to categorize events in the sectors covered by this report. Additional information on the INES classification can be found on the CNSC website.

2.2 Data collection

Compliance ratings, non-compliance data, and CNSC enforcement actions were obtained from the CNSC’s compliance verification and enforcement program in 2015.

Annual compliance reports submitted by licensees in calendar year 2015 provided the data on doses incurred by all persons engaged in licensed activities in the four sectors covered in this report.

2.3 Changes in 2015

Under the Commission’s direction, CNSC staff introduced the following changes:

- As of 2015, performance results for Class IB accelerator facilities will now be covered under the Regulatory Oversight Report for Nuclear Processing, Small Research Reactors and Class IB Accelerator Facilities.

- Compliance ratings for the management system SCA will be included in the report’s overall section.

- A list of all reported events from the four sectors covered has been included as Appendix D

3 Regulatory program for the use of nuclear substances

The possession, use, transfer, import, export, abandonment and storage of nuclear substances must be licensed by the CNSC when the amount of nuclear substance involved is greater than its exemption quantity (see Schedule 1 of the Nuclear Substances and Radiation Devices Regulations. Facilities where certain types of Class II prescribed equipment are installed must also be licensed by the CNSC prior to their construction, operation or decommissioning. A licence is also required to service radiation devices or Class II prescribed equipment.

All licensees that operate Class II nuclear facilities or that service a Class II prescribed equipment must have a certified radiation safety officer and a qualified temporary replacement. The radiation safety officer has the responsibility of the radiation protection program, ensuring that licensed activities are conducted safely and that all regulatory requirements are met.

All radiation devices and Class II prescribed equipment, as well as certain types of transport packages, must be certified by the CNSC before they can be used in Canada.

An integral part of the CNSC’s regulatory oversight is the compliance and verification program, which measures licensee compliance with CNSC regulatory requirements. Regular inspections and desktop evaluations verify that licensees comply with the Nuclear Safety and Control Act (NSCA) and its associated regulations, as well as the conditions of their licences.

To determine appropriate levels of regulatory monitoring and control, CNSC staff establish compliance verification plans for each nuclear sector that are based on risk-informed regulatory oversight of each sector’s activities. Modifications to the compliance plans are made on an ongoing basis in response to events and changes in licensees’ performance.

For the activities covered in this report, the CNSC’s risk-informed regulatory program is applied in the following way:

- Each licensed activity is assigned a weighting factor – a coefficient that represents the activity’s relative significance with respect to risk.

- Factors considered in weighting include the form of the nuclear substances (e.g., sealed source, unsealed source or radiation device), the location where the material is being used (e.g., a work site or a controlled facility), and the compliance history of licensees conducting licensed activities.

- Generally, licensees are inspected at a predetermined frequency of five years or less, based on their risk ranking.

The risk-informed regulatory program provides:

- a risk ranking that recognizes the potential safety impact of the licensed activity

- an effective and informed allocation of regulatory oversight effort according to the risk ranking by licensed activity and by licensee performance history

- an effective, transparent, consistent and comprehensive regulatory oversight

3.1 CNSC regulatory effort

The CNSC’s risk-informed regulatory program applies resources and regulatory oversight commensurate with the risk associated with the regulated activity. Regulatory effort related to licensing, certification and compliance verification is derived from this program. A total of 1,568 inspections were completed in 2015. As shown in Table 1, the CNSC staff direct effort for regulating the use of nuclear substances in 2015 amounted to close to 13,400 person days or the annual equivalent of approximately 59 full-time staff.

| Activity | Person days |

|---|---|

| Licensing | 5,015 |

| Certification | 1,564 |

| Compliance verification | 7,372 |

3.2 Licensing

To obtain a licence, an applicant must submit an application to the CNSC. The CNSC will issue a licence only when the applicant:

- is deemed qualified to carry on the activity that the licence will authorize

- has demonstrated that it will protect the health and safety of persons and the environment

- has demonstrated that it will maintain national security

- has confirmed that it will adhere to international obligations to which Canada has agreed

CNSC staff perform a rigorous technical assessment of applications submitted to the CNSC. Each is assessed based on the risk ranking of proposed licensed activities.

The CNSC has produced a series of licence application guides that outline application expectations to ensure that the CNSC’s expectations for licence applications are clear and to facilitate applicants’ interactions with the regulator. These guides are reviewed regularly to ensure they continue to reflect modern regulatory expectations and provide useful guidance to the regulated community. This practice, in turn, facilitates CNSC licensing reviews and minimizes regulatory burden. Application forms and guides can be found on the CNSC website for nuclear substances and radiation devices as well as for Class II facilities and prescribed equipment.

When applying for licence renewals, existing licensees are subject to the same scrutiny as new applicants. The CNSC decision to renew a licence is based on the application information submitted as well as a satisfactory compliance performance history. This includes a review of compliance information such as inspection results, reported incidents and events, and annual compliance reports.

If the application satisfies the above requirements, the Commission, or a designated officer authorized by the Commission, may issue a licence authorizing the licensee to conduct the activities requested in the application. The licence includes provisions that define and limit the scope of the authorized activities, as well as specific conditions that must be fulfilled by the licensee when conducting those activities.

3.2.1 Licence consolidation strategy

The CNSC has developed a licence consolidation strategy aimed at reducing administrative burden on organizations that hold multiple licences for various licenced activities such as hospitals and universities. This strategy included creating and issuing new consolidated licences for Class II nuclear facilities as well as reviewing the licence format and process for those that use nuclear substances and radiation devices.

Consolidation of Class II nuclear facility licences has allowed the CNSC to, for example, authorize a hospital with a medical linear accelerator to operate and service the accelerator under one licence instead of two. In other cases, it has allowed cancer centres to include several types of radiotherapy activities to be covered under a single licence instead of as many as five. In some cases, such as operating a cyclotron and radiation therapy facilities, licence consolidation is not desired since each licensee’s radiation protection program and management structure is different.

The majority of licences issued through the Directorate of Nuclear Substance Regulation are for the possession and use of nuclear substances and radiation devices. A comprehensive evaluation of the licensing process will be conducted in early 2016 as the first part of the implementation strategy to streamline the application process and reduce the number of licences required. Due to the number of licences and the volume of ongoing work, changes to the licensing approach must be carefully considered to minimize the impact on licensees. CNSC staff will continue to work with stakeholders, including the Canadian Radiation Protection Association/CNSC Working Group, to ensure that proposed changes will not adversely impact their operations while retaining strong regulatory oversight. As part of an ongoing improvement process, CNSC staff continue to review the licensing application guide and forms to clarify expectations for applicants. This led to the October 2015 revision of REGDOC-1.6.1, Licence Application Guide: Nuclear Substances and Radiation Devices, which provided greater clarity and simplified requirements for applicants.

The number of licences issued by sector is shown in table 2 and the distribution of licences by select groups is provided in figure 2. Most licensees, as represented by the industry sector, perform one licensed activity and, therefore, require only one CNSC licence. Hospitals tend to conduct various licensed activities, such as diagnostic nuclear medicine, cancer therapy, production and processing of nuclear medicine isotopes and human research. These disparate activities are covered under specific CNSC licences which reflect the unique characteristics of such uses. As a result, hospitals typically hold more than one CNSC licence. In addition, a number of provinces are in the process of combining the administration of several hospitals under new provincial authorities. CNSC staff will continue to work with these licensees to ensure that there is the appropriate level of regulatory control while minimizing administrative burden wherever possible.

| Sector | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Medical | 568 | 561 | 552 | 536 | 494 |

| Industrial | 1,456 | 1,451 | 1,440 | 1,398 | 1,349 |

| Academic and research | 276 | 253 | 232 | 229 | 207 |

| Commercial | 250 | 248 | 256 | 248 | 245 |

| Total | 2,2550 | 2,513 | 2,480 | 2,411 | 2,295 |

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Description

| Sector | 1 | 2-3 | 4-6 | 7-9 | 10+ |

|---|---|---|---|---|---|

| Hospitals | 14.2% | 58.2% | 16.4% | 6.7% | 4.5% |

| Industrial sector | 88.6% | 9.7% | 1.2% | 0.4% | 0.2% |

| All sectors combined | 79.5% | 15.9% | 3.1% | 0.9% | 0.5% |

3.3 Certification of prescribed equipment

An application for certification must be submitted to the CNSC before the prescribed equipment can be used in Canada. CNSC staff who conduct the technical evaluations of applications for certification are accredited as professional engineers as part of their job requirements. Upon receipt of an application, CNSC staff conduct a thorough technical review of the information contained in the submission to determine if:

- the radiation device, Class II prescribed equipment or transport package meets all CNSC regulatory requirements and is safe to use

- adequate measures are in place in respect of their use in order to protect the environment, national security, and the health, safety and security of persons

A CNSC quality assurance program, in the form of a peer review by another CNSC staff member, is in place for the review of new applications for certification of prescribed equipment and those where significant changes are made to the original design.

If satisfied that the design meets the above requirements, the Commission, or a designated officer authorized by the Commission, may issue a certificate for the radiation device, Class II prescribed equipment or transport package based on the recommendation of the CNSC staff member who conducted the technical evaluations.

If the design does not comply with the above requirements or if a certified model is found to be unsafe, the designated officer will contact the applicant and all affected parties, such as users in the case of a certified model, to inform them of the decision to either not certify the new model or to decertify a currently certified model. In these cases, the CNSC will provide the applicant and affected parties an opportunity to be heard in accordance with the process specified in the regulations.

Regulatory documents RD/GD-254, Licence Application Guide: Certification of Radiation Devices or Class II Prescribed Equipment and RD/GD-352, Design, Testing and Performance of Exposure Devicesoutline CNSC expectations for the certification of radiation devices and Class II prescribed equipment, while RD/GD 364, Joint Canada - United States Guide for Approval of Type B(U) and Fissile Material Transportation Packages, outlines CNSC expectations for the certification of transport packages. CNSC staff are reviewing RD/GD-254 and RD/GD-352 as part of the CNSC’s commitment to maintaining a modern regulatory framework.

3. 4 Certification of exposure device operators

In 2015, the CNSC certified 141 new exposure device operators (EDO) and renewed the certification of 240 certified EDOs.

Licensees are required under the Nuclear Substances and Radiation Devices Regulations to permit only CNSC-certified personnel and supervised trainees to use exposure devices containing nuclear substances. In industrial radiography, nuclear substances are used in exposure devices for the non-destructive examination of materials.

The CNSC EDO certification program is designed to ensure the continued competency of the operator, and maintain the safety and security of persons and devices when working with exposure devices. Certified individuals must demonstrate the ability to:

- handle, transport, store and operate exposure devices and any accessories to the devices safely and securely

- properly utilize radiation detection and monitoring equipment

- understand the obligation to comply with all relevant regulatory requirements

Since the CSA Group implemented its Certified Exposure Device Operator Personnel Certification Guide (CSA PCP-09) in 2015, certified EDOs must renew their certification every five years. This ensures that every certified EDO maintains the knowledge and skills required to operate an exposure device safely. To verify that EDOs have valid certifications, CNSC inspectors check EDO certification cards during inspections.

The CNSC may take regulatory action if the EDO is found to be operating contrary to safety protocols and conditions, or if the EDO is causing undue risk to the public or the environment.

3.5 Certification of Class II radiation safety officers

All licensees that operate Class II nuclear facilities or that service Class II prescribed equipment must have a certified radiation safety officer (RSO) and a qualified temporary replacement. The RSO ensures that licensed activities are conducted safely and all regulatory expectations are met.

There are two components to the RSO certification process:

- an assessment of the candidate’s capabilities to perform the duties of the position, based on the submitted application

- an assessment of the candidate’s knowledge of the licensed activities, based on an examination

RSO candidates must possess certain qualifications before they can be considered for certification. For most Class II licensed activities, candidates must have at least a bachelor’s degree in engineering or science from a recognized universityFootnote 1. Alternative education qualifications may be reviewed on a case-by-case basis.

If the candidate is able to clearly demonstrate their knowledge, as it relates to the RSO position within their organization, the Commission or a designated officer authorized by the Commission may certify the candidate in the position of RSO.

The process for certification of Class II RSOs, along with guidance for applicants, is outlined in REGDOC-2.2.3, Personnel Certification: Radiation Protection Officers.

In 2015, the CNSC certified 17 of 19 applicants as Class II RSOs. In both cases where applicants failed to meet certification requirements, the licensee nominated another person to serve as RSO.

3.5.1 Class II RSO examination

The content of the examination focuses on five subjects:

- relevant provisions of the NSCA and its ensuing regulations

- principles of radiation safety

- radiation physics

- operational activities and facilities which are to be licensed by the CNSC

- radiation protection program of the facility

The content of the examination is tailored to:

- the operational risks of the licensed activity

- the organization’s policies and procedures

- the candidate’s academic background and work experience

Since the implementation of the certification of Class II RSO in 2005, the CNSC has certified approximately 200 RSOs. The CNSC plans to administer all Class II licence application examinations online in late 2016. (Examinations are currently conducted orally, either in person or over the telephone.) The change is expected to assist the CNSC enhance objectivity when examining candidates, and shorten the certification process for each candidate.

3.6 RSO appointment for nuclear substances and radiation device licences

There are approximately 2,300 RSOs appointed for nuclear substances and radiation device licences. The designation of RSO for nuclear substances and radiation devices licences is the responsibility of the person responsible for the management and control of the licensed activity. The RSO is the person the CNSC will contact about radiation safety and compliance matters. The appointment of these RSOs does not involve a certification process.

The CNSC requires the RSO’s qualifications be included in a licence application and will determine if the RSO has sufficient knowledge and expertise with regards to the applicant’s proposed activities. The RSO may be a consultant hired by the applicant to carry out this role, provided that the consultant is clearly designated by the applicant authority to do so. Such information must be communicated to the CNSC as part of the licence application process. Alternate RSOs may be utilized where a licensee has multiple locations of licensed activity.

Unless otherwise noted by the applicant authority, the RSO will be considered to have the authority to act for the applicant and will have signing authority for all matters encompassed by the CNSC licence.

For high-risk activities, CNSC staff perform additional verifications. They meet with applicant RSOs during a pre-licensing visit to verify the RSO’s knowledge of the company’s radiation protection program and confirm the applicant’s understanding of their obligations as a licensee. Staff plan visits and prepare the interview following review of the application and the applicant’s radiation protection program. During the visit, CNSC staff review the location of the proposed licensed activities while ensuring that candidates have strong radiation safety knowledge as well as advanced training in operational and emergency procedures. If it is deemed that the appointed RSO does not have adequate knowledge, the licensing decision will be pending on the appointment of a suitable RSO.

3.7 Licensing and certification decisions

In 2015, CNSC designated officers made a total of 2,579 licensing and certification decisions. The majority of these were licensing decisions in relation to activities covered in this report, as shown in Table 3. In addition, the Commission amended 2,332 licences in 2015 to include licence conditions related to new requirements for financial guarantee and security of sealed sources.

Even after factoring for this increase in the number of licence amendments, there was an increase in the number of licensing decisions made in 2015. This increase was partly due to the cyclical nature of licence renewals as well as an increase in the number of licence transfers. For every new licence transfer, such as when there is a change to the corporate number, the old licences are revoked and a new licence is issued under the new corporate number. The CNSC has developed a simplified licence transfer form to facilitate these transactions.

| Type of decision | Number of decisions |

|---|---|

| Licensing (issuance of new licences, licence renewals, licence amendments, licence revocations and licence transfers) | 2,089 |

| Certification of prescribed equipment (radiation devices, Class II prescribed equipment and transport packages) | 92 |

| Certification of EDOs (issuance of new certification and renewal of certification | 381 |

| Certification of Class II RSOs | 17 |

| Total | 2,579 |

3.8 Compliance verification and enforcement

The CNSC verifies compliance by conducting site inspections and reviewing licensee documentation and operational activities. Licensees are required to report routine performance data through annual compliance reports and the occurrence of specific types of events. In addition, the CNSC conducts investigations of unplanned events, public complaints or accidents involving nuclear substances.

The CNSC uses a graded approach to enforcement to encourage compliance and deter future non-compliances. When a non-compliance (or a continued non-compliance) has been identified, CNSC staff assess its risk and safety significance in order to determine appropriate enforcement action. The chosen enforcement action is commensurate with the risk that the non-compliance presents to the environment, the health and safety of workers and members of the public, and to national security. Enforcement actions vary with non-compliance severity, and can include orders and administrative monetary penalties. Each is a discrete and independent response to a non-compliance.

In 2015, CNSC staff conducted 1,568 inspections to verify compliance with CNSC regulatory requirements, including 217 enhanced security inspections to verify compliance against the requirements of REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources. Escalated compliance enforcement actions were taken against licensees in the medical, industrial, academic and research, and commercial sectors in 21 instances. The majority of them were in response to inspection findings.

As part of CNSC staff efforts to consolidate compliance activities, the CNSC transferred compliance verification activities related to the import and export of high-risk sealed sources in the sectors covered in this report to the Directorate of Nuclear Substance Regulation. Field inspections were initiated in 2016. Additional information on the results of these inspections will be included in the 2016 edition of this regulatory oversight report.

3.8.1 Mobile Inspection Kit project

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Also part of the CNSC’s continuous improvement process, the Mobile Inspection Kit (MIK) project makes use of new technologies to better equip CNSC inspectors in performing their compliance verification activities. The CNSC’s MIK is an electronic application developed for use on a tablet. As shown in Figure3 , the MIK enables CNSC inspectors to easily capture inspection findings and results, generate inspection reports, and transfer inspection data to CNSC databases electronically.

The MIK project was launched as a two-phase pilot in 2014. The first phase involved a group of CNSC inspectors performing a few inspections and gathering feedback on how the tool and process could be improved. In late summer 2015, additional CNSC inspectors were equipped with tablets in a much wider pilot. The second phase of the pilot project involved the development of an online portal through which licensees will be able to download preliminary inspection reports about their facilities and activities. This version was released in the spring of 2016, and further piloting of this final phase will occur over the year. The pilot phase of the project is expected to be completed in late 2016.

While the feedback gathered so far shows that some items still need to be addressed, tablets clearly have a useful and significant role to play in a mobile regulatory environment. In September 2015, the Canadian Association of Members of Public Utility Tribunals (CAMPUT) presented the 2015 CAMPUT Award for Innovation and Leadership to the CNSC for the MIK project.

Building on collaboration with the Community of Federal Regulators in 2014, CNSC staff delivered a tailored presentation on the MIK project to Transport Canada and the National Energy Board. Both organizations plan to launch similar initiatives.

3.9 Reporting

Licensees are expected to meet all regulatory reporting requirements, as prescribed in the NSCA, its associated regulations and their licence conditions. In addition to the submission of their annual compliance reports on licensed activities, licensees are required to immediately report on specific types of events related to licensed activities that require immediate mitigating measures by the licensee.

3.10 Stakeholder engagement

Clarity of requirements is one of the CNSC’s corporate priorities. Stakeholder engagement and outreach are two tools the CNSC uses to meet this priority. Outreach and engagement lead to an increased awareness and better understanding of the regulatory process and requirements. These, in turn, lead to increased workplace safety. CNSC staff take all opportunities to perform outreach, including while on inspection.

Outreach sessions held throughout Canada in 2015 provided licensees and other persons the opportunity to interact with the regulator outside the scope of an inspection or licensing activities.

3.10.1 Outreach sessions

Since 2009, the CNSC has offered an outreach program for licensees that use nuclear substances and prescribed equipment. The presentations made by CNSC staff and discussions associated with outreach are meant to inform licensees and other persons regulated by the CNSC on recent and upcoming regulatory changes, and provide education regarding the CNSC’s expectations for licensing and compliance requirements.

In 2015, the CNSC outreach program addressed recent and upcoming regulatory developments and other areas of regulatory focus, such as:

- the importance of maintaining proper inventory control of nuclear substance and prescribed equipment

- the importance of reviewing previously approved procedures

- changes to the CNSC licensing program such as financial guarantees and a revised licence application guide

- changes to the compliance verification program, such as the use of MIK tablets among inspectors and electronic inspection reports

- reporting requirements related to skin contamination events

- reporting requirements related to annual compliance reports

- the new Packaging and Transport of Nuclear Substances Regulations, 2015

- new security expectations in REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources

- upcoming changes to the Radiation Protection Regulations

3.10.2 Newsletters

In 2009, the CNSC introduced the DNSR Newsletter as an outreach vehicle for disseminating regulatory and safety information to licensees that use nuclear substances and prescribed equipment in Canada. The newsletter articles address various regulatory compliance issues and support the regulator’s commitment to keep both licensees and the public informed. Regular editions of the newsletter provide valuable information to licensees in all sectors; special editions focus on either a specific subsector or an area of regulatory interest.

All newsletters are posted on the CNSC website and are sent to recipients on the CNSC subscription list. In addition, in 2015, CNSC added direct delivery of the newsletter to licensee RSOs by email in order to better reach its target audience and improve distribution among licensees and their workers.

Two DNSR Newsletter editions were published in 2015: one regular and one special edition. The regular edition provided information on the financial guarantee program, reported events presented to the Commission during the past year, and the discussion paper DIS-14-02, Modernizing the CNSC’s Regulations. The special edition focused on the importance of maintaining control of sealed sources and how to prevent loss of control.

3.10.3 Industrial radiography working group

In 2009, a CNSC industrial radiography working group was established to foster improved communications between the CNSC and the industry. The working group meets twice a year to discuss best practices and safety performance, and provides a forum in which stakeholders can stay informed of new developments from both technical and regulatory perspectives. The CNSC holds two separate annual meetings with the radiography industry-at-large, one in Leduc, AB, and the other in Ottawa, ON. Staff use these meetings to address recent and upcoming regulatory developments and discuss other areas of regulatory focus. The meetings act as a venue for industry members to communicate with CNSC staff, ask questions and share information on best practices and lessons learned. Staff routinely provide and discuss trending data on compliance with regulatory requirements.

In 2015, several presentations were delivered on the EDO certification process (PCP-09) implementation from both CNSC and Natural Resources Canada perspectives. Guest presentations were delivered on the importance of maintenance and inspection of exposure devices and on safety culture. The meeting in Leduc, AB, was attended by approximately 70 participants. The meeting in Ottawa, ON, was the best-attended annual eastern meeting to date, with 22 participants.

The industrial radiography working group meetings took place in Calgary and Edmonton, AB. The group reviewed previous meeting minutes, discussed items of interest and planned for the outreach strategy for the industry-at-large meetings.

3.10.4 Canadian Radiation Protection Association working group

In 2014, a working group was established between the CNSC and the Canadian Radiation Protection Association (CRPA). In 2015, this working group continued its efforts to promote strong radiation safety cultures within licensed facilities. The working group approved its terms of reference in 2015. The CRPA shared these terms with its members.

For almost three decades, CNSC staff have delivered regulatory-focused presentations and participated in regulatory workshops at the CRPA’s annual conferences. At the 2015 conference in Winnipeg, MB, CNSC staff delivered several presentations relating to events that occurred earlier in 2015 and to reporting requirements for specific types of events. CNSC managers also participated in a panel discussion on various regulatory topics. A virtual meeting was also held in September 2015, keeping with plans for the group to meet at least twice annually.

3.10.5 Canadian Organization of Medical Physicists

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

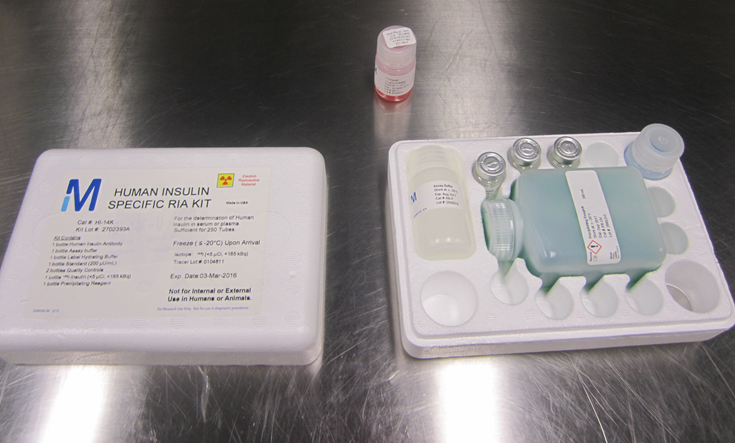

The Canadian Organization of Medical Physicists (COMP) represents medical physicists working in radiotherapy facilities in the medical sector. Many certified radiation safety officers at Class II nuclear facilities are members of COMP.

In 2015, CNSC staff delivered presentations and posters on regulatory issues (shown in Figure 4 ) at the COMP annual conference, attended the COMP winter school and submitted quarterly articles on regulatory topics of interest to radiotherapy licensees to InterACTIONS, COMP’s professional newsletter. In order of publication date, the article topics included:

- presenting the 2013 edition of this regulatory oversight report at the November 2014 Commission meeting

- safety culture

- correcting inaccurate submissions

- a retrospective of the regulatory process for Class II facilities

The winter school was attended by 80 people, the majority of which were physicians, physicists and radiation therapists from Canada, the United States and India. Highlights of the 2015 winter school included a talk about the characteristics of high reliability organizations and strategies for managing change.

3.10.6 Portable gauge workshops

Established in 2014, the CNSC regulatory workshop for portable gauge licensees was created to promote compliance and safety culture within this industrial subsector. The workshops consist of presentations delivered by CNSC staff, a question-and-answer session and general discussions. The presentations focus on radiation protection, compliance programs, worker training, transport of nuclear gauges and reporting requirements. CNSC staff developed this workshop in response to negative trending data related to the use of enforcement actions against licensees in this subsector.

CNSC staff offered 14 portable gauge workshops across Canada in 2015. Positive results have already been observed. There has been a marked improvement in compliance among, and fewer CNSC enforcement actions taken against, the licensees in the portable gauge subsector. CNSC staff will continue offering these workshops in 2016.

4 Regulatory developments

This section provides details of the regulatory developments that took place in 2015 and 2016 relating to regulatory programs for licensees covered in this report.

4.1 Packaging and Transport of Nuclear Substances Regulations, 2015

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

The packaging and transport of nuclear substances is jointly regulated by the CNSC and Transport Canada. Packages that are used for the transport of nuclear substances, some of which are shown in Figure 5, must comply with the CNSC’s Packaging and Transport of Nuclear Substances Regulations, 2015 (PTNSR 2015), with Transport Canada’s Transportation of Dangerous Goods Regulations and the International Atomic Energy Agency’s (IAEA) Regulations for the Safe Transport of Radioactive Material 2012 Edition.

In June 2015, the Government of Canada published the PTNSR 2015 in the Canada Gazette, Part II. These revised regulations align to the IAEA transport regulations and ensure continued alignment by including an ambulatory reference, which adopts future editions of the international regulations as they become available.

These revised regulations clarified existing requirements and ensured continued safe and efficient transport of nuclear substances. In particular, they provide additional clarity in the areas of radiation protection program requirements, reporting requirements, the transport of large objects and the discovery of material containing unidentified nuclear substances. For example, the PTNSR 2015 includes new provisions related to the transport of material containing unidentified nuclear substances discovered while in transport. Some examples include:

- shipments containing scrap metal coming from oil drilling operations

- domestic waste containing medical isotopes from patients that have undergone medical procedures

- shipments containing contaminated materials such as metal shelving and kitchenware

A new exemption has been introduced for those shipments that have low radiation dose rates. This exemption allows for limited movement of these shipments provided the CNSC is notified, allowing for their safe transport and proper characterization.

In addition to the PTNSR 2015, REGDOC-2.14.1, Information Incorporated by Reference in Canada’s Packaging and Transport of Nuclear Substances Regulations, 2015 was published in February 2016. This document serves as a technical reference document, linking provisions of the PTNSR 2015 to relevant content in the IAEA regulations, as well as the Nuclear Safety and Control Act (NSCA), CNSC regulations, and other related information.

4.2 REGDOC-1.6.1, Licence Application Guide: Nuclear Substances and Radiation Devices

In October 2015, REGDOC-1.6.1, Licence Application Guide: Nuclear Substances and Radiation Devices, became the standard regulatory document that sets out guidance for applicants when preparing and submitting applications for licences to carry out activities related to nuclear substances and radiation devices. The new document provides additional information on CNSC’s regulatory expectations and includes forms that applicants can use or modify to suit their application needs.

4.3 REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources

Mandatory compliance with REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources came into effect on May 31, 2015 for licensees with category 1 and 2 high-risk sealed sources. Licensees with category 3, 4 or 5 sealed sources must comply with regulatory requirements by May 31, 2018Footnote 2. The regulatory document sets out the minimum security measures to prevent the loss, sabotage, illegal use, illegal possession or illegal removal of sealed sources while in transport or in storage. The measures take into consideration aggregate quantities of radioactive sources. REGDOC 2.12.3 is aligned with the IAEA Code of Conduct as well as IAEA Nuclear Security Series (NSS) 14 Nuclear Security Recommendations on Radioactive Material and Associated Facilities.

To ensure proper regulatory oversight of these new requirements, CNSC inspectors have been conducting enhanced security inspections for those in possession of high-risk sealed sources. In 2015, CNSC staff conducted 217 enhanced security inspections. Details on these inspections are not provided in this report due to their sensitive nature.

4.4 Financial guarantee licence condition

In 2015, the CNSC introduced a new licence condition requiring licensees to provide financial guarantees that there will be sufficient resources to terminate their licensed activities safely. When licensees terminate their activities, they must properly account for the safe disposal of all licensed material and equipment, and demonstrate that all locations associated with the licence are free of radioactive contamination. A financial guarantee does not relieve licensees from complying with regulatory requirements for termination of licensed activities. However, it ensures that there are funds available to the CNSC when licensees are unable to carry out safe termination. Whereas financial guarantees are well established for Class I nuclear facility licences, this is the first time such a program has been implemented for licensees in the nuclear substance sectors. This new requirement came into effect on April 1, 2015. All licensees are in compliance.

4.5 CSA Standard PCP-09, Certified Exposure Device Operator Personnel Certification Guide

In November 2015, CSA standard PCP-09, Certified Exposure Device Operator Personnel Certification Guide, replaced the CNSC’s G-229, Certification of Exposure Device Operators. The new guidance document details the requirements for exposure device operator certification and offers guidance on the best way to achieve and maintain certification. CNSC staff are overseeing a phased implementation to ensure a successful transition to the standard.

4.6 Guidance on the handling of the deceased implanted with nuclear substances

Following a request by stakeholders for clarification, CNSC staff are developing guidance for the handling of the deceased that have been implanted or injected with nuclear substances as well as those that have inhaled or ingested nuclear substances. The guidance is intended for coroners, and funeral home and crematorium workers. It can be used when providing services to families of deceased patients who have undergone diagnosis or therapy using nuclear medicine. It will inform readers of the risks that are present (minimal in all cases) and recommend best practices to help keep doses to the workers, families and the public at ALARA levels.This document is expected to be drafted in 2016 and published for consultation in early 2017. The information will be included in REGDOC-2.7.1, Radiation Protection, in a section for the handling of the deceased.

4.7 Regulatory focus in 2016

The CNSC focus in 2016 will continue to be on effective regulatory oversight and continuous improvement, including:

- undertaking a lean assessment of regulatory program in order to optimize internal processes for delivery of efficient regulatory program

- reviewing the licensing process and continuing the consolidation of licences

- separation of the licensing and compliance activities for import and export of Category 1 and 2 sealed sources

- leveraging experience from inspecting Class II facilities in a move to concentrate on more complex inspections across all sectors

- clarifying expectations for reportable events with the development of regulatory document REGDOC-3.1.2, Part II, Reporting Requirements for Nuclear Substances and Radiation Devices to clarify regulatory reporting requirements for situations listed in the regulations

- enhancing oversight of RSOs across all sectors

- implementation of regulatory document REGDOC-2.1.2, Safety Culture, which provides information on safety culture applicable to all licensees and sets out requirements and guidance related to fostering a healthy safety culture.

- Increasing focus on performance based inspections

5. Safety performance – all sectors combined

This section provides an overview of the overall performance of the industry sectors covered in this report.

5.1 Overall safety assessment

CNSC staff conducted 1,568 inspections across all sectors in 2015 to verify compliance with CNSC regulatory requirements, including 217 enhanced security inspections to verify new security requirements. All sectors continued to demonstrate adequate performance within all safety and control areas (SCAs). The majority of inspected licensees in 2015 were found to be compliant in the four SCAs covered in this report:

- In management system, 96.2 percent of licensees ensured that adequate processes and programs were in place to achieve their safety objectives.

- In operating performance, 90.6 percent of licensees made adequate provisions for the health, safety and security of persons, and protection of the environment.

- In radiation protection, 88.7 percent of licensees continued to ensure that exposure of workers and the public to ionizing radiation remained as low as reasonably achievable.

- In security, 95 percent of licensees demonstrated that they have adequate provisions in place to prevent the loss, sabotage, illegal use, illegal possession or illegal removal of sealed sources and prescribed equipment in their care and control.

For those in possession of high-risk sealed sources, enhanced security inspections were conducted in 2015. Of those inspected, 77.4 percent (168 of 217 inspections) were found to be compliant with the regulatory requirements. Licensees have put in measures to correct all non-compliances identified during these inspections. The majority of non-compliances for enhanced security requirements were administrative items related to security plans.

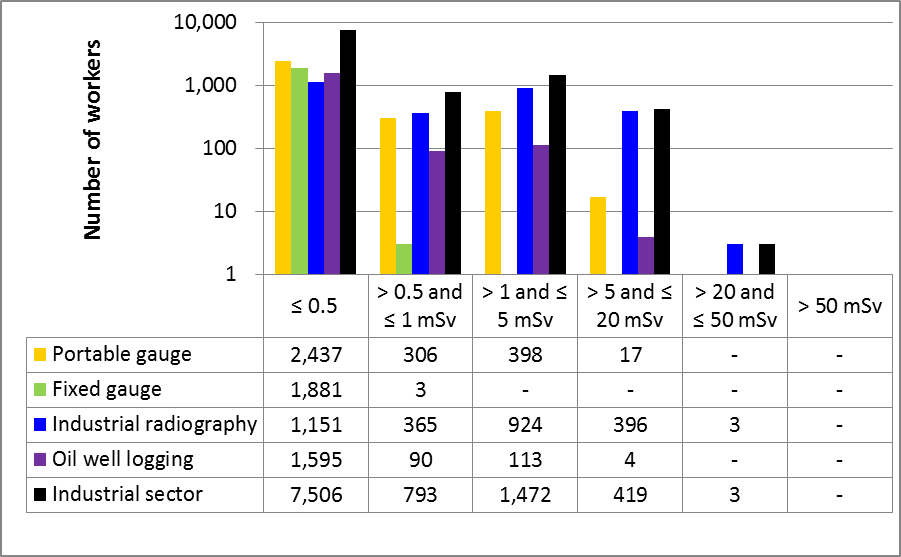

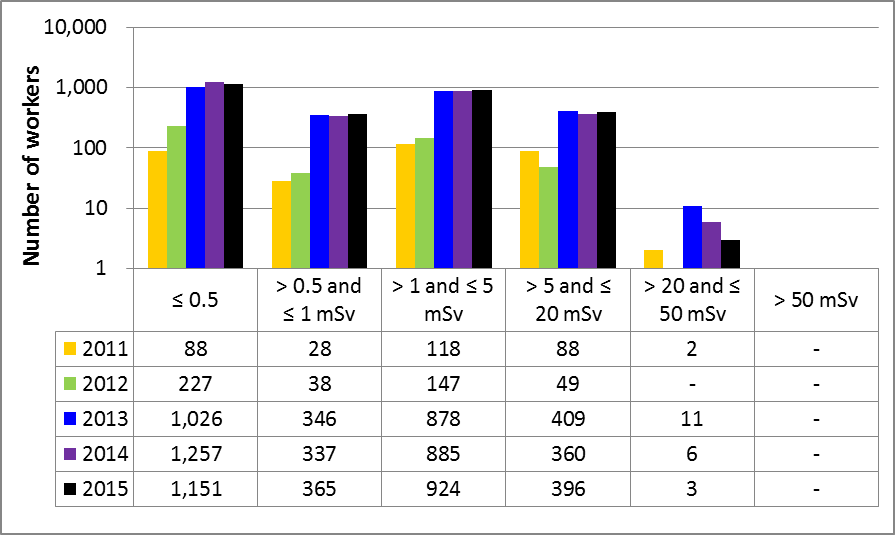

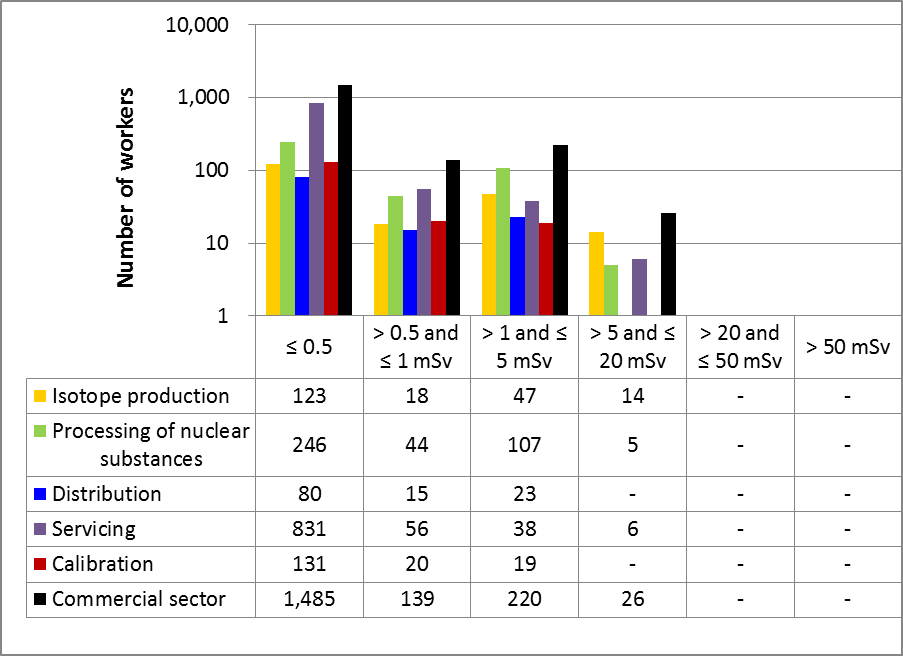

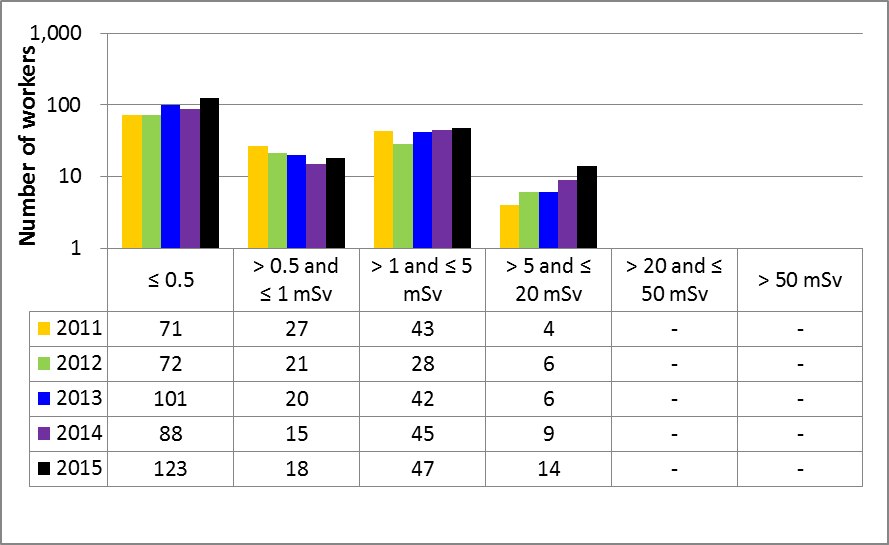

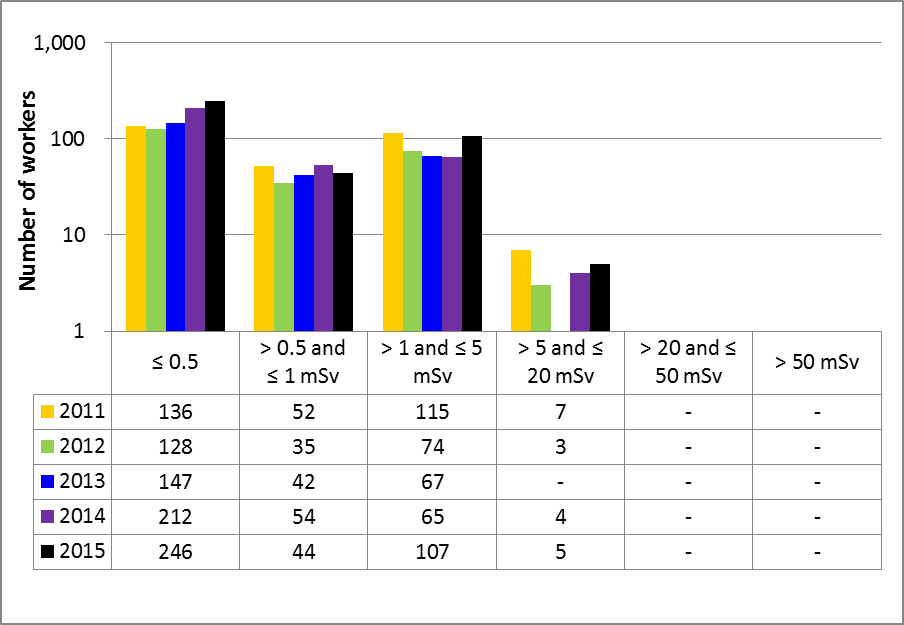

Effective dose to workers continued to be below regulatory limits in 2015, consistent with previous reporting years. Doses for 53,700 workers were reported to the CNSC in the four sectors covered in this report. Of those workers, 22,322 were designated as nuclear energy workers (NEWs) while 31,378 were not designated as NEWs.

One NEW received an equivalent dose above the regulatory limit for extremities of 500 millisieverets (mSv) as a result of an event that was reported to the Commission in June 2015. Further details on this event are provided in section 5.8.

Apart from this event, neither workers (designated as NEWs or not) nor members of the public exceeded applicable effective regulatory dose limits in 2015.

For 2015, CNSC staff assessed all 155 events reported by the licensees and which are covered in this report. Reported events have been ranked using the International Nuclear and Radiological Event Scale. Of these, 149 were ranked as level 0 (no safety significance), six were ranked as level 1 (anomaly) and one was ranked as level 2 (incident). The level 2 event involved the worker who received a dose that exceeded the applicable regulatory limit mentioned above.

For all of the events reported, licensees implemented appropriate response measures to mitigate the impacts of the events and to limit radiation exposure to workers and the public. CNSC staff reviewed the measures put in place by licensees and found them to be satisfactory.

5.2 Management system

The management system SCA covers the framework that establishes the processes and programs required to ensure that an organization achieves its safety objectives, continuously monitors its performance against those objectives, and fosters a healthy safety culture.

All sectors demonstrated satisfactory performance within the management system SCA, with 96.2 percent of inspected licensees (1,233 of 1,282 inspections) found to be in compliance with regulatory requirements. A breakdown of the inspection ratings for 2015 is shown in Table 4.

The majority of non-compliances in this SCA included conducting activities contrary to a licence, failure to comply with regulatory requirements related to having records at work locations, and failure to notify the CNSC of changes in contacts for licensed activities. For licensees such as hospitals that hold multiple licences for various activities, non-compliances observed during inspections mostly related to inadequate management oversight of their radiation protection program.

| Rating | All sectors combined | Medical | Industrial | Academic and research | Commercial |

|---|---|---|---|---|---|

| Fully satisfactory or satisfactory | 1,233 | 227 | 837 | 67 | 102 |

| Below expectations | 49 | 15 | 23 | 4 | 7 |

| Unacceptable | 0 | 0 | 0 | 0 | 0 |

| Total | 1,282 | 242 | 860 | 71 | 109 |

| Percent compliant (%) | 96.2 | 93.8 | 97.3 | 94.4 | 93.6 |

5.3 Operating performance

Operating performance refers to the licensee’s ability to perform licensed activities in accordance with pertinent operational and safety requirements defined in the Nuclear Safety and Control Act (NSCA), its associated regulations and licence conditions. Licensees are expected to demonstrate that they comply with operational and safety requirements by providing workers with appropriate procedures for the safe use of nuclear substances and prescribed equipment, by ensuring that workers follow procedures, and by maintaining records that demonstrate compliance.

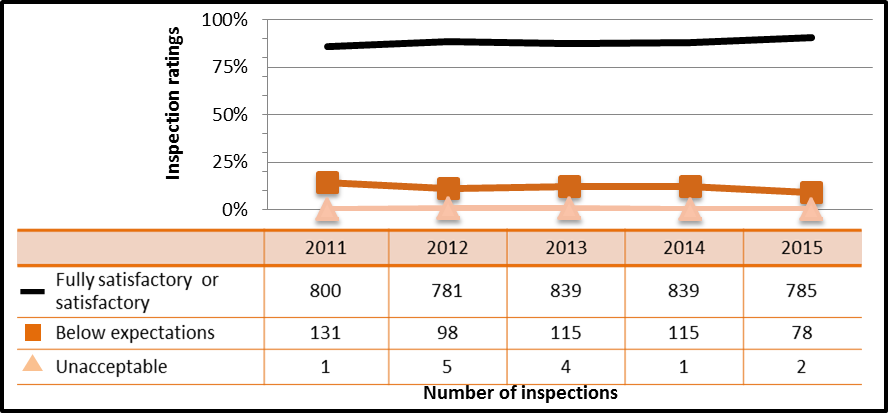

All sectors continued to demonstrate adequate performance within the operating performance SCA in 2015, with 90.6 percent of inspected licensees (1,181 of 1,303 inspections) found to be in compliance with regulatory requirements.

Two inspections received unacceptable ratings in the operating performance SCA in 2015. In both cases, the inspectors issued orders to portable gauge licensees to ensure corrective actions were taken immediately. Compliance with regulatory requirements is unacceptable when compliance within the overall SCA is significantly below expectations, or there is evidence of systemic failure in safely conducting activities. Without immediate corrective action, there is a high probability that the deficiencies will lead to an unreasonable risk.

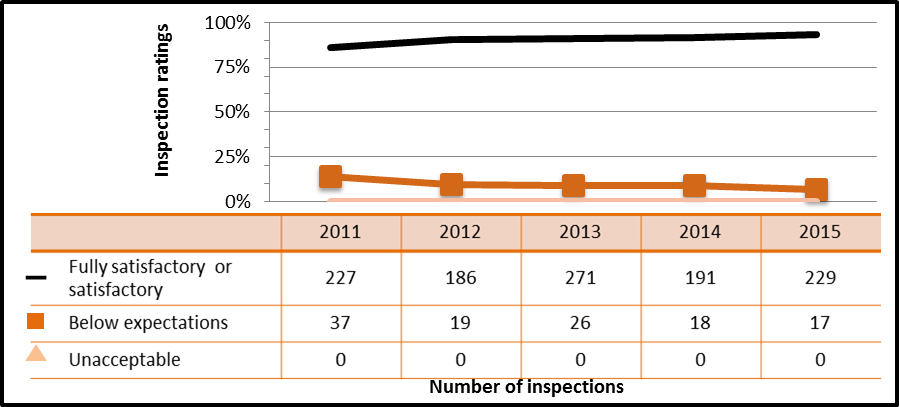

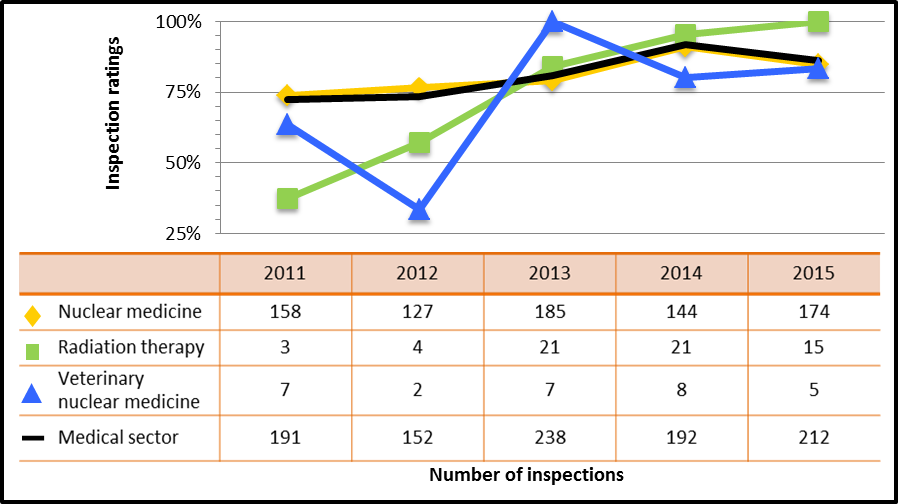

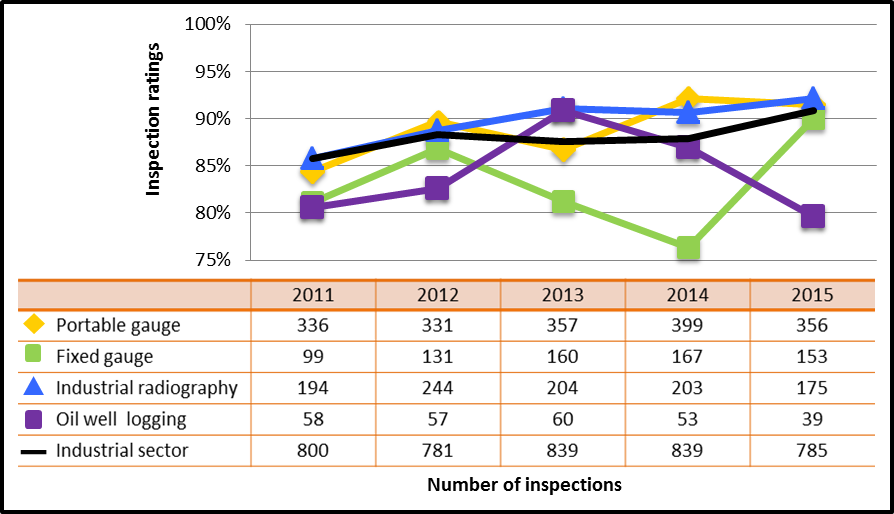

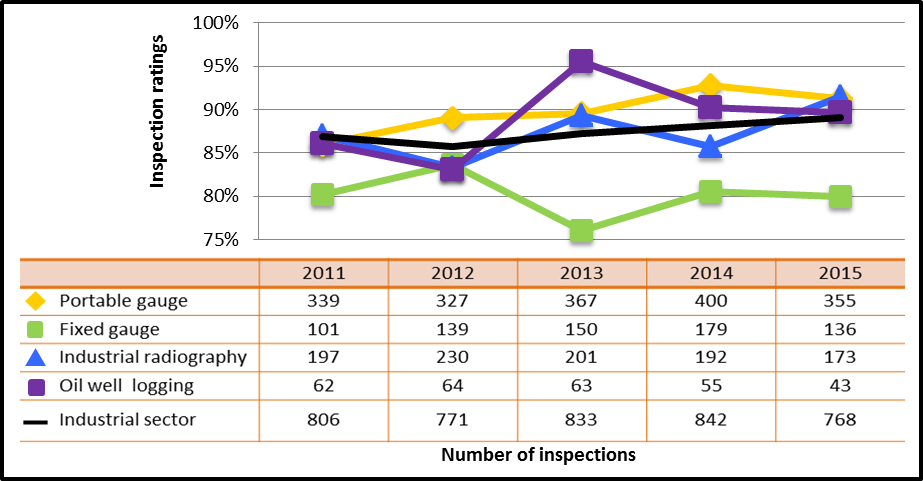

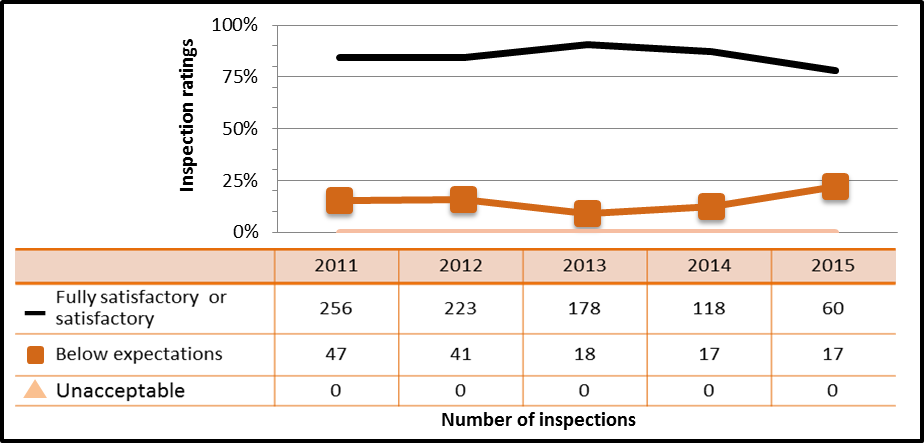

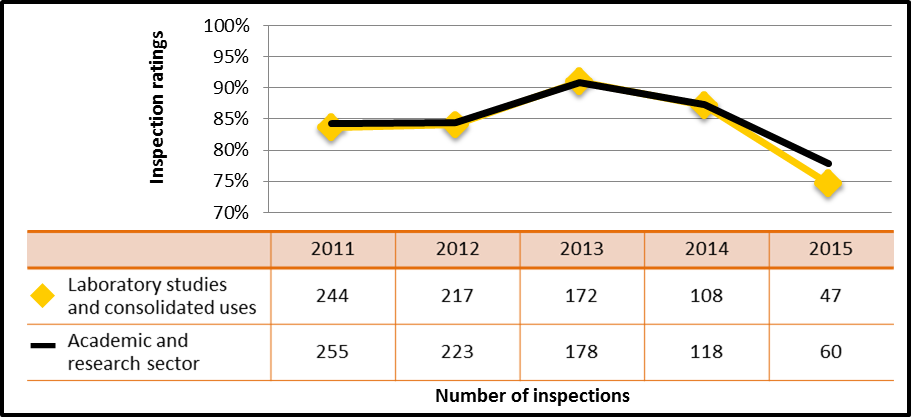

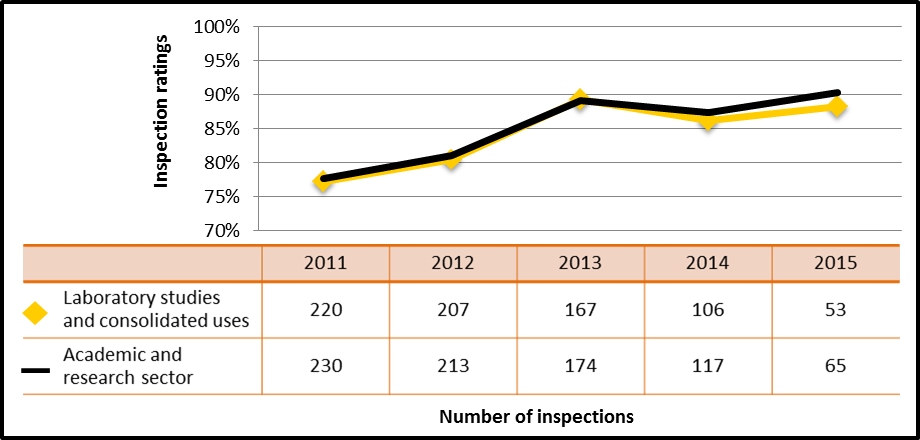

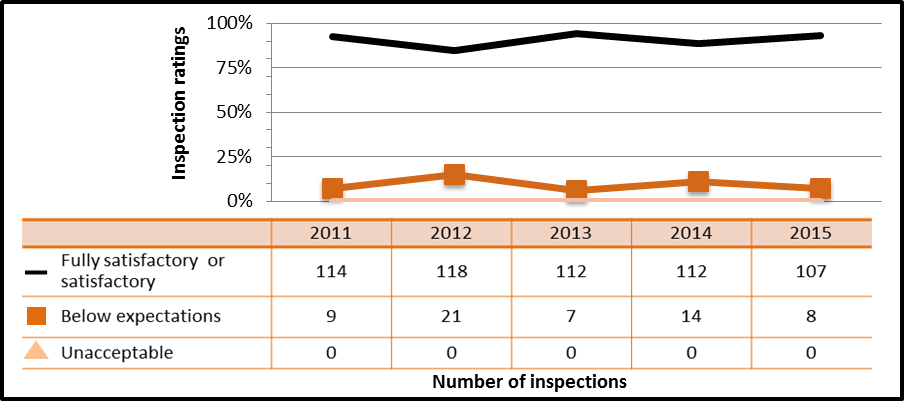

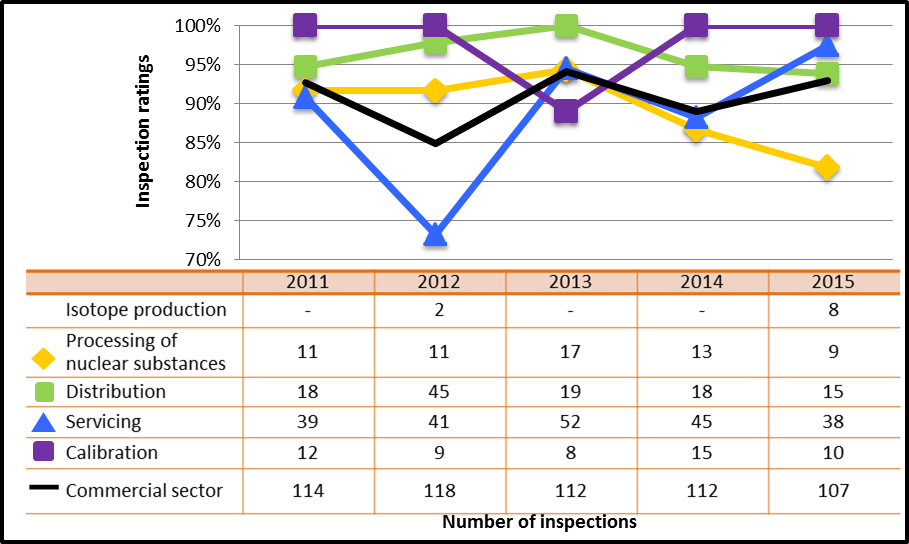

Inspection ratings for all sectors combined are shown in Figure 6 and a sector-to-sector comparison appears in Figure 7. Despite the stability of the overall industry, the academic and research sector rating in this SCA has been trending negatively since 2013. As a response to this trend, CNSC staff have modified a component of their outreach strategy to increase focus on this sector in 2016.

The majority of non-compliances in this SCA included failure to comply with regulatory requirements related to retention of records, worker obligations, and sealed source leak testing.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Description

| Inspection ratings | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Fully satisfactory | 1,397 | 1,308 | 1,400 | 1,260 | 1,181 |

| Below expectations | 224 | 179 | 166 | 164 | 120 |

| Unacceptable | 1* | 5* | 4* | 1* | 2* |

* Order Issued to licensee

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Description

| Sector | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Fully satisfactory or satisfactory | 1,397 | 1,308 | 1,400 | 1,260 | 1,181 |

| below expectations | 224 | 179 | 166 | 164 | 120 |

| Unacceptable | 1* | 5* | 4* | 1* | 2* |

5.4 Radiation protection

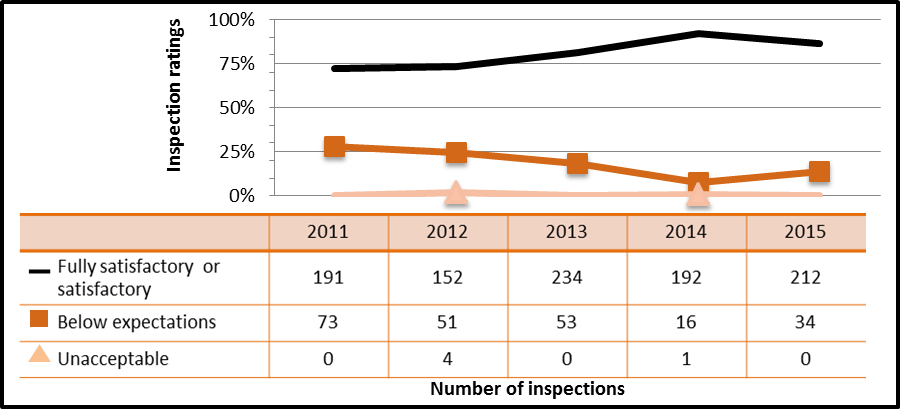

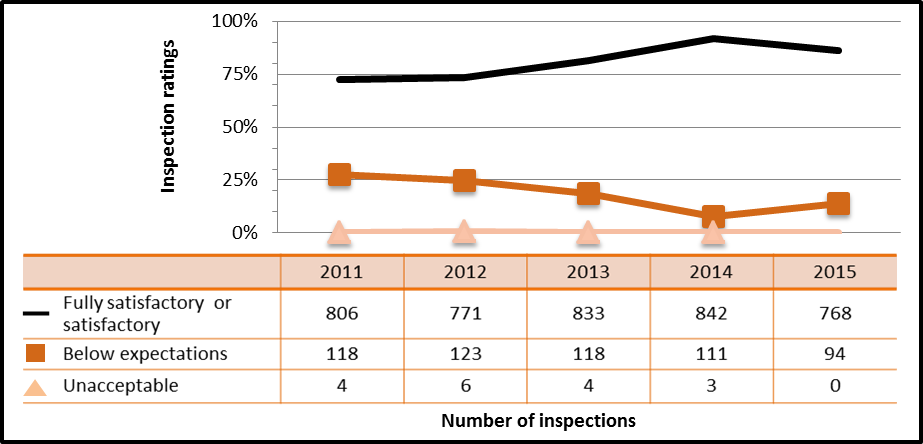

Radiation protection programs are required for every licensee to ensure that contamination levels and radiation doses received by workers are monitored, controlled and maintained below regulatory dose limits, and kept at levels that are as low as reasonably achievable (ALARA), social and economic factors being taken into account. Licensees are expected to monitor worker doses, post radiation warning signs, plan appropriately for radiological emergencies, manage oversight of operational activities, institute effective workplace practices that emphasize the use of time, distance and shielding to minimize exposure to radiation, and use appropriate protective equipment.

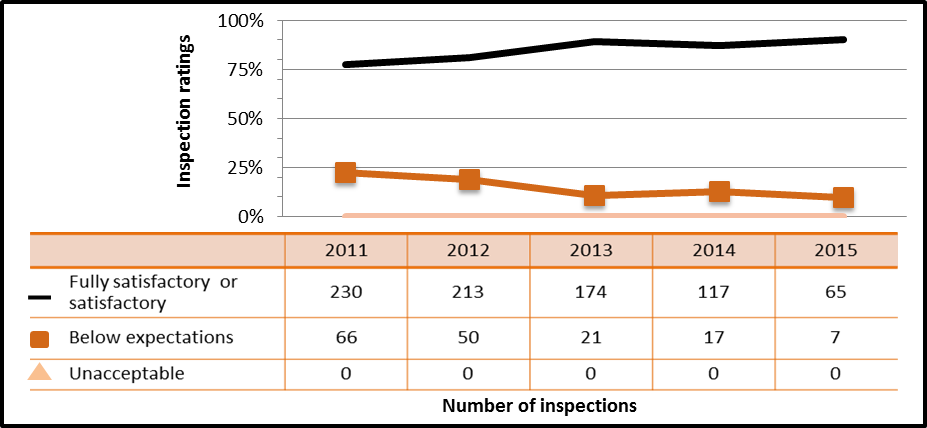

All sectors demonstrated adequate performance within this SCA, with 88.7 percent of inspected licensees (1,151 of 1,297 inspections) found to be compliant with regulatory requirements. The remaining inspected licences received ratings of below expectations.

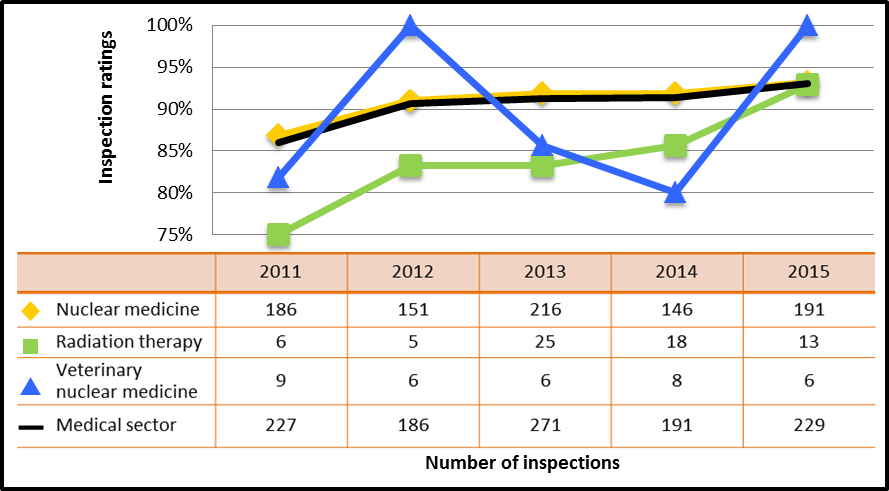

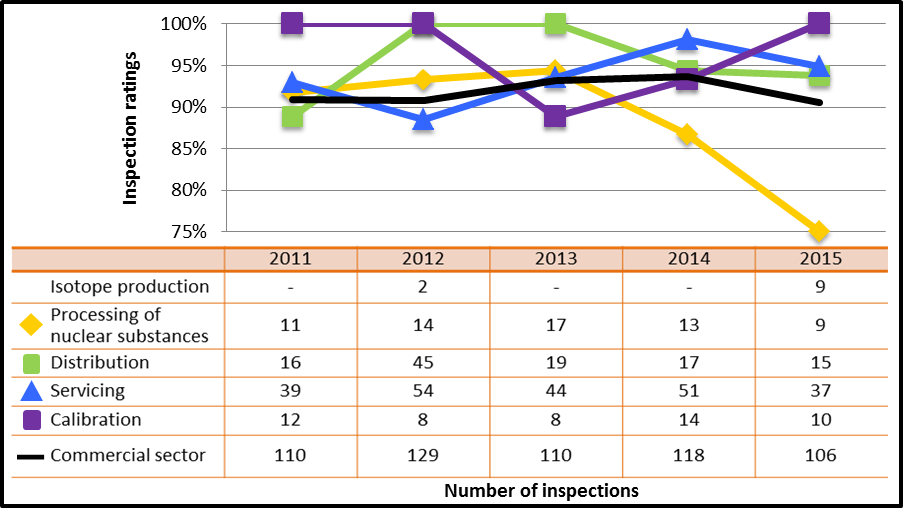

Inspection ratings for all sectors combined are shown in Figure 8. A sector-to-sector comparison is presented in Figure 9. The majority of non-compliances included survey meters not being calibrated, inadequate implementation of measures to ensure that doses are kept ALARA, and improper posting of signs at boundaries and points of access.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Description

| Inspection ratings | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Fully satisfactory or satisfactory | 1,397 | 1,265 | 1,351 | 1,269 | 1,151 |

| Below expectations | 268 | 237 | 200 | 152 | 146 |

| Unacceptable | 4* | 10* | 4* | 4* | 0* |

* Order Issued to licensee

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Description

| Inspection ratings | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Medical | 191 | 152 | 234 | 192 | 212 |

| Industrial | 806 | 771 | 833 | 842 | 768 |

| Academic and research | 230 | 213 | 174 | 117 | 65 |

| Commercial | 110 | 129 | 110 | 118 | 106 |

| All sectors combined | 1,337 | 1,265 | 1,351 | 1,269 | 1,151 |

5.5 Security

Licensees are required to have in place physical security measures, practices and programs to prevent the loss, illegal use, illegal possession or illegal removal of nuclear substances during their entire lifecycle, including while they are in storage or during transport. The extent of the security measures required depends upon the types of nuclear substances used and activities performed by each licensee.

Overall, all sectors showed satisfactory ratings for the security SCA in 2015, with 95 percent of inspected licensees (1,149 of 1,210 inspections) found to be compliant with regulatory requirements. Two inspections were given an “unacceptable” rating and resulted in the inspector issuing an order to each licensee to ensure corrective actions were taken immediately.

CNSC staff verified licensee compliance against requirements described in REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources. For those in possession of high-risk sources, enhanced security inspections were conducted in 2015. Of those inspected, 77.4 percent (168 of 217 inspections) were found to be compliant with regulatory requirements.

Licensees addressed and corrected all non-compliances identified during inspections to the satisfaction of the CNSC. Table 5 summarizes the performance of all sectors combined for this SCA for 2014 and 2015, while Table 6 provides a sector-to-sector comparison for both years.

| Rating | 2014 | 2015 |

|---|---|---|

| Fully satisfactory or satisfactory | 1,265 | 1,149 |

| Below expectations | 69 | 59 |

| Unacceptable | 0 | 2 |

| Total | 1,334 | 1,210 |

| Percent compliant (%) | 94.8 | 95 |

| Sector | 2014 | 2015 | ||

|---|---|---|---|---|

| Number of inspections | Percent compliant (%) | Number of inspections | Percent compliant (%) | |

| Medical | 188 | 96.3 | 223 | 98.2 |

| Industrial | 931 | 94 | 828 | 94.2 |

| Academic and research | 123 | 97.6 | 70 | 91.4 |

| Commercial | 92 | 96.7 | 89 | 96.6 |

| All sectors | 1,334 | 94.8 | 1,210 | 95 |

Compliance with the mandatory tracking of high-risk sealed sources was satisfactory in 2015. Of the 134 inspected licensees, 119 (or 91 percent) were found to be compliant with this requirement. CNSC staff ensured that the 12 instances of non-compliances were adequately addressed by the licensees. The majority of non-compliances for high-risk sealed source tracking requirements were administrative items such as incorrect or misidentification of licensee addresses, device information or source location.

Further information on this topic is available in the National Sealed Source Registry and Sealed Source Tracking System Annual Report.

5.6 Enforcement actions

In 2015, the CNSC escalated 21 compliance enforcement actions against licensees in the medical, industrial, academic and research, and commercial sectors. CNSC staff issued orders and directed licensees to take immediate corrective measures in 15 instances, as shown in Figure 10. In each case, the licensee immediately complied with the order. Once the CNSC was satisfied that the licensee had addressed the order’s terms and conditions, the order was closed. All orders issued in 2015 are closed. CNSC designated officers issued administrative monetary penalties (AMPs) in six instances in 2015, all of which have been paid. A breakdown of the 21 enforcement actions is provided for each of the sector while a summary of orders and AMPs taken by the CNSC in 2015 is provided in appendix C. Further information on regulatory actions, including escalated enforcement actions, taken by the CNSC is also available on the CNSC website.

The CNSC decertified one exposure device operator in 2015. This stemmed from an inspection in 2014 that identified non-compliances relating to the use of survey meters and supervision of exposure device operator trainees. Due to a significant health and safety risk, an order was issued to the company requiring them to immediately remove the certified exposure device operator from all activities related to the use of an exposure device until it was demonstrated to the CNSC that the operator was no longer likely to pose a risk to the health and safety of persons.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Description

| Sector | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Medical | N/A | N/A | N/A | N/A | 2 |

| Industrial | 13 | 16 | 24 | 16 | 14 |

| Academic and research | 1 | N/A | N/A | 2 | 1 |

| Commercial | N/A | 1 | N/A | 1 | 4 |

| All sectors combined | 14 | 17 | 24 | 19 | 21 |

5.7 Reported events

Licensees are required to have programs in place for the management of unplanned events and accidents. The situations that warrant mandatory reporting and the content of the reports are set out in the NSCA, its regulations and the conditions of their licence. CNSC staff review, assess and track all events reported by licensees.

Reported events have been ranked using the International Nuclear and Radiological Event Scale (INES), a tool for communicating the safety significance of nuclear and radiological events to the public. This tool allows the establishment of a proper perspective of an event’s safety significance. The scale has been used to classify events at nuclear power plants since 1990 and has been extended over the years to apply to all nuclear industry installations. By 2006, it had been adapted to all events associated with the transport, storage and use of radioactive sources and nuclear substances. Note that the scale is not a tool to compare safety performances among facilities or organizations, but to effectively communicate the safety significance of events.

In 2015, there were 155 events related to nuclear substances reported to the CNSC by licensees in the sectors covered in this report. Of these events, 149 were ranked as INES level 0 (no safety significance) and six were ranked as level 1 (anomaly) based on the quantity of nuclear substances involved and the type of event reported (stolen portable gauges).

The remaining event – ranked as level 2 (incident) – occurred when a NEW received an extremity dose of 1.7 Sv, which is above the regulatory limit of 500 mSv. Further details on this event and effective doses to the workers are provided in section 5.8.

A breakdown of reported events by type is shown in Figure 11 and a complete list of all reported events in 2015 is provided in appendix D.

For all of the events reported, the licensees implemented adequate response measures to mitigate the impacts of the events and to limit radiation exposure to workers or any radiological impact on the environment. CNSC staff reviewed these measures, along with licensee corrective actions to prevent recurrence of the events, and found them to be satisfactory.

As part of their final, detailed reports on events, licensees are required to identify probable causes of events and propose corrective actions to prevent recurrence. In many cases, probable causes were related to workers not following procedures. As a result, the majority of measures taken by licensees to prevent recurrence related to retraining staff on procedures and emphasizing the importance of procedural adherence.

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

Description

| Sector | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Malfunctioning or damaged devices | 60 | 52 | 51 | 52 | 53 |

| Spills, contamination or release | 24 | 31 | 39 | 39 | 17 |

| Missing or found nuclear substances | 17 | 18 | 17 | 17 | 20 |

| Packaging and transport | 23 | 27 | 26 | 30 | 47 |

| Breach of security | 5 | 11 | 17 | 9 | 5 |

| Unplanned exposure | N/A | N/A | N/A | N/A | 13 |

| All reported events | 129 | 139 | 150 | 147 | 155 |

Note: Unplanned exposure is listed as a discrete event for the first time in this year’s report. It represents those events that have led to non-routine exposures to workers or members of the public. Events of this type in previous years were covered under breach of security.

5.7.1 Malfunctioning or damaged devices

.png/object?subscription-key=3ff0910c6c54489abc34bc5b7d773be0)

There were 53 events related to damaged or malfunctioning devices of systems. Of these, 39 were reported as damaged devices:

- Fourteen involved damage to portable gauges, which were hit or run over by vehicles at construction sites, as shown in Figure 12

- Eleven involved damage to fixed gauges, with most events related to damage to the shutter handle

- Eleven involved damage to exposure devices following a drop or an impact

- two involved receipt of a damaged irradiated target

- one involved damage to a X-ray fluorescence analyzer from a drop

None of the above resulted in damage to the source or resulted in source leakage. There was no release to the environment or exposure to members of the public as a result of these events.

The remaining 14 events corresponded to malfunctioning devices:

- five involved malfunctioning fixed gauges where the shutter failed to close properly

- four involved malfunctioning exposure devices where the sealed source failed to retract into the shielded position or the device failed the pre-operation verifications

- two involved malfunctioning portable gauges

- one involved a malfunctioning device discovered while conducting a radiation survey

- one involved error codes associated with use of a brachytherapy unit

- one involved an intrusion alarm found to be not working properly

All malfunctioning devices were taken out of service as required by the Nuclear Substances and Radiation Devices Regulations. Any radiation exposure to a person as a result of the events was well below the annual public regulatory dose limit of 1 mSv. All of the events in this section are closed.

5.7.2 Spill, contamination or release

All licensees are required to document, record and investigate every skin contamination event to ensure work practices are optimized and to minimize the probability of repeat occurrences. None of the spill, contamination or release events reported in 2015 posed a risk to the environment or resulted in members of the public receiving a dose.

There were 17 events related to spills, unplanned releases or contamination of personnel reported:

- Twelve involved contamination resulting from mishandling of unsealed nuclear substances

- two involved spills during the production of gallium-68

- one involved a spill of copper-61 inside a cyclotron vault

- one involved a release of gaseous carbon-11 to the environment through an exhaust system

- one involved a release of solid waste to the environment above allowable release limits by 0.003 megabecquerel per kilogram

These events only include situations where spills or contamination occurred outside of fume hoods, hot cells or other normal means of containment. The nuclear substances involved had half-lives ranging from a few hours to a few days. In all cases, workers received doses well below the annual public regulatory dose limit of 1 mSv. These events had a negligible impact on the environment or the public. All of these events are closed.

5.7.3 Missing or found nuclear substances

Licensees are required to have in place physical security measures, practices and programs to prevent the loss, illegal use, illegal possession or illegal removal of nuclear substances during their entire lifecycle, including while they are in storage or during transport.

In 2015, there were 20 reported events involving lost or stolen nuclear substances and one report of a found nuclear substance. The sealed sources or radiation devices were recovered in seven of the 20 instances. At the time of writing, eight events remained under investigation. The sealed sources or radiation devices had not yet been recovered. A further five events were closed, as there was very low risk associated with the nuclear substances involved and/or the type of event reported.

Events involving lost, stolen or recovered radiation devices and sealed sources are reported in the Lost or Stolen Sealed Sources and Radiation Devices Report, which is updated regularly. Table 7 provides a summary of the events that occurred in 2015.

| # | Date | Event summary | Sealed source category | INES rating level | Status |

|---|---|---|---|---|---|

| 2393 | Jan. 21 | Four excepted packages containing very low-risk sources (i.e., static eliminators) were delivered to a licensee, but could not be located following receipt. | 5 | 0 | Sources not recovered. Event closed as the radioactive sources involved are of very low risk. |

| 2400 | Feb. 2 | Two vials of technetium-99m (4.9 GBq) were reported missing from a storage location. | N/A | 0 | Nuclear substance not recovered. Event closed as the nuclear substances involved had a short half-life. |

| 2503 | Feb. 10 | A sample of mixed isotopes used for testing was reported missing. | N/A | 0 | Nuclear substance recovered. Event closed. |

| 2370 | Feb. 12 | Six fixed gauges containing low-risk sources were reported missing from a licensed facility by a CNSC inspector during an inventory check. | 4 | 0 | Fixed gauges found |